|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Have a Question / Feedback ? | Submit- only questions about this website will be answered | Search Our Site |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Historical Specifics:

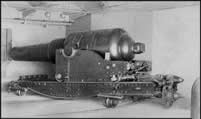

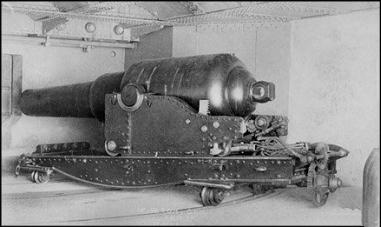

Only four of this nature of gun were used in New South Wales. Three were installed in the Upper casemate at Georges Head being moved from Upper Georges Heights and Middle Head in 1886. They were replaced in 1892. According to the 1901 Report two of this nature of gun were located at South Head, one at Victoria Barracks (in the School of Gunnery) and one (No135) at Bare Island. In 1912 Bare Island began use as a War Veterans Home (ceased use in 1962) and the casemate in which the 10 inch had been positioned was converted into use as a billiard room by laying a timber floor. In 1975, whilst the timber floor was being removed, the barrel No 135 was found buried beneath. Today that barrel is on display in the casemate mounted on a timber carriage for display purposes only. Originally it would have been mounted on a carriage iron sliding dwarf similar to the one shown in the following photo of a similar gun at the Upper Casemate, Georges Head in 1886.

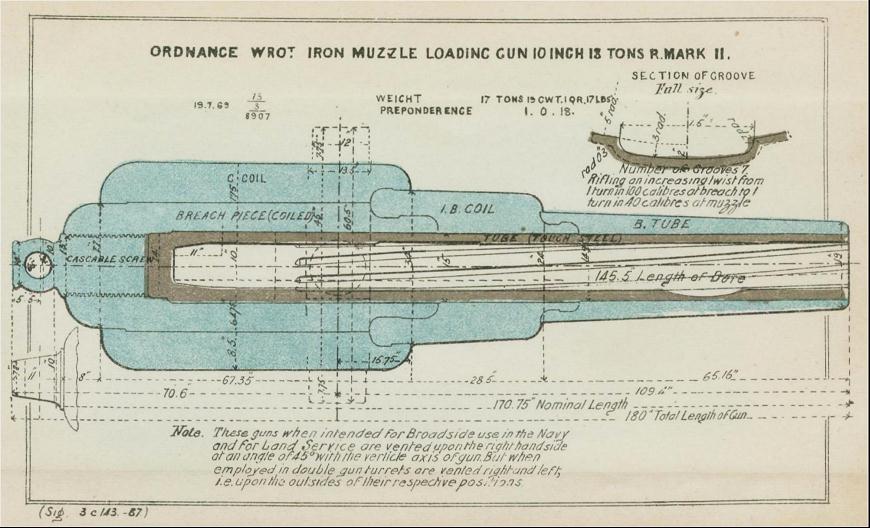

RML 10 inch Mark II 18 ton

In 1888 Major William St Pierre Bunbury, Royal Artillery, Military Instructor NSW published Notes on Elementary Gunnery. His book was a compilation of information on artillery with specific emphasis on those guns in service in New South Wales. It includes the following details on the construction of the 10 inch 18 ton Mark II gun. 10” R.M.L. gun (Woolwich system) of 18 tons. The 10" 18-ton gun Mark II, the gun in use in the service of this Colony, consists of:

The A tube is made from a solid ingot of steel which is rough and fine bored, and toughened by heating it and plunging it in a bath of oil. The breech piece consists of two coils united together by shrinkage and welding, the breech piece is shrunk on to the steel tube, and turned down. The 1 B coil is a single thick coil turned down after welding, and bored out, and shrunk on to the A tube, and over the end of the breech piece. The B tube consists of two single and slightly taper coils welded together, turned and bored, and shrunk on to the end of the 1 B coil and the front of the A tube. The breech piece has a screw thread cut in its breech end for the reception of the cascable, which is made of the best scrap iron threaded, and a gas escape channel cut through the threads, and one round of the thread at the end turned off, forming an annular space, into which gas would pass, in case of any crack in the steel tube, and escape by the escape channel or “tell-tale.” The cascable is screwed in before the jacket is shrunk on, and the gun is rifled at this stage to avoid the extra work required to turn such a heavy mass as the complete gun. The C coil or jacket consists of a breech coil, trunnion ring, and ring coil, the two coils being double, and the trunnion ring of forged iron. The breech coil and ring coil have a piece turned off their inner ends to receive the trunnion ring which is heated to redness and dropped over the shoulder of the breech coil, the muzzle coil is then dropped down on the breech coil within the trunnion ring, which contracts round the two coils; the whole mass is then welded together, turned down, bored, and shrunk on the gun over the breech piece, and hooking on to the 1 B coil.. The gun is then ready for the final turning, lapping, and finishing operations, rough vented for proof, proved, examined, and sighted. |

||||

|

||||

Photo from original NSW School of Gunnery Photograph Album (RAAHC) |

||||

|

||||

Everywhere Whither Right and Glory Lead |

||||